Flavor Stability in Non-Alcoholic Beer: Key Challenges

Non-alcoholic beer is growing fast, but keeping its flavor stable is tough. Here's why:

- Market Growth: Expected to reach $43.9B by 2034, with a 7.9% CAGR from 2024-2034.

- Flavor Issues: Lacks alcohol's natural preservative, leading to chemical changes, storage challenges, and taste inconsistencies.

-

Key Problems:

- Chemical Changes: Compounds like aldehydes cause "cardboard" flavors.

- Storage Effects: High temperatures and oxygen exposure speed up staling.

- Taste Challenges: Risks of spoilage and inconsistent profiles due to residual sugars and microbial growth.

-

Solutions:

- Use advanced brewing methods (e.g., cold contact fermentation, special yeast strains).

- Select high-quality raw materials like low-lipoxygenase barley.

- Optimize production with better packaging, enzyme applications, and microbial stabilization.

Brewers must adopt modern techniques and strict quality control to meet rising demand for flavorful non-alcoholic beers. Keep reading for detailed strategies and success stories.

Improve your beer quality control

Main Flavor Stability Issues

Non-alcoholic beer faces unique challenges in maintaining flavor stability, primarily because it lacks alcohol's natural preservative qualities. Let's break down the key issues: chemical changes, storage effects, and taste profile inconsistencies.

Chemical Changes

Beer flavor is influenced by a complex mix of 600–700 compounds . Among these, certain chemical changes can significantly impact taste:

| Compound Type | Impact on Flavor | Detection Threshold |

|---|---|---|

| Aldehydes | Cardboard-like taste (E-2-nonenal) | As low as 0.1 ppb |

| Ketones | Sweet, fruity notes | Varies by compound |

| Heterocyclic compounds | Caramel, burnt sugar notes | Depends on the compound |

Experts Charles W. Bamforth and Aldo Lentini highlight the difficulty of maintaining flavor stability:

"Perhaps the biggest remaining quality challenge for brewers is the achievement of flavor stability. Achieving flavor stability is a major challenge, especially as what happens to the beer in between packaging and consumption is often out of the control of the brewer."

These chemical shifts often worsen during storage, compounding the problem.

Storage Effects

Temperature and oxygen exposure play a major role in how non-alcoholic beer ages. For example, a 10°C increase in storage temperature can speed up staling by two to three times . A study showed that beer stored at 37±1°C faced rapid flavor degradation:

- Furanic compounds: Developed 140 times faster

- Aldehydes: Formed 90 times faster

- Esters: Produced 20 times faster

Additionally, oxygen exposure - always present in air at 21% - is a major issue for non-alcoholic beers, which lack alcohol's protective qualities .

Storage conditions, especially temperature and oxygen levels, are critical to preserving the beer's intended taste.

Taste Profile Challenges

Maintaining a consistent flavor in non-alcoholic beer is no easy task. These beers face several sensory issues:

- Higher microbial risks due to the absence of alcohol's antimicrobial properties

- Residual sugars from incomplete fermentation increase the chances of spoilage

- Variability in aging behaviors makes it harder to ensure flavor consistency

To address these issues, brewers must adopt strict quality control practices, including reducing oxygen exposure and ensuring reliable cold storage .

sbb-itb-a752bf8

Solutions for Better Flavor Stability

Maintaining flavor stability in non-alcoholic beer requires a combination of modern brewing techniques, careful raw material selection, and advanced production methods.

Modern Brewing Methods

Cold contact fermentation (CCF) has become a popular method for improving flavor stability. By controlling yeast activity at lower temperatures, CCF produces favorable higher alcohols and esters while minimizing unwanted worty flavors .

Here are some specialized brewing techniques and their key points:

| Method | Benefits | Challenges |

|---|---|---|

| Membrane Dealcoholization | Precisely separates alcohol while retaining flavor | High upfront costs and requires expertise |

| Arrested Fermentation | Easier for craft breweries and uses natural processes | Demands strict temperature control |

| Limited Fermentation | Boosts flavor development and is cost-efficient | Needs specific yeast strains |

Brewers are also exploring alternative yeast strains like Pichia kluyveri and Hanseniaspora uvarum, which produce minimal ethanol but generate desirable flavor compounds .

Escarpment Labs has introduced a specialized yeast for non-alcoholic beer:

"NAY is our maltose-negative yeast that makes brewing non-alcoholic beers easier." - Escarpment Labs

These brewing approaches are paving the way for further advancements in materials and production.

Raw Material Selection

The quality of raw materials plays a big role in flavor stability. For instance, Carlsberg Research Laboratory has developed low-lipoxygenase barley cultivars that reduce E-2-nonenal levels, a compound linked to flavor deterioration .

Key practices for better flavor stability include:

- Choosing barley varieties rich in natural antioxidants.

- Using specialty malts made under controlled kilning conditions.

- Timing hop additions before the end of wort boiling.

- Incorporating hop oils to prevent "hop creep" .

For non-alcoholic beer, achieving an original gravity of 4.0–7.5 wt.% with 25–30% fermentability helps create a stable and consistent flavor profile .

New Production Methods

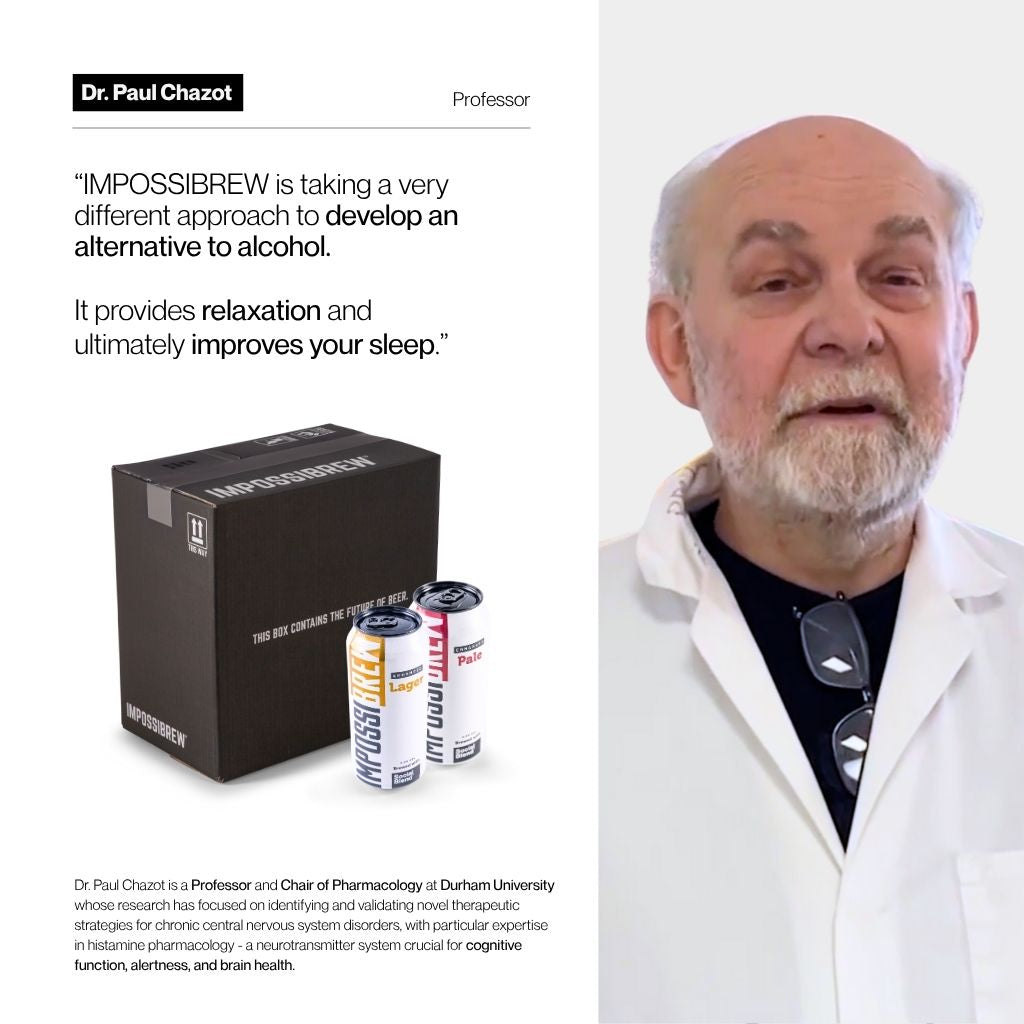

In addition to raw materials, modern production techniques ensure consistent flavor profiles. IMPOSSIBREW® demonstrates this with its proprietary Social Blend™ technology, designed to maintain traditional beer flavors without alcohol.

Key considerations for production include:

-

Microbial Stabilization

Pasteurization or filtration helps prevent unwanted fermentation and keeps flavors consistent . -

Enzyme Applications

Proteases and lipases can fine-tune and stabilize flavor compounds, offering better control over the beer's taste . -

Storage Optimization

Advanced packaging, like crown cork liners with low oxygen permeability, helps preserve flavor during storage .

Additionally, modified mashing techniques now allow brewers to limit starch conversion into fermentable sugars, offering more control over the final product's flavor . The industry continues to explore new ways to enhance flavor stability while meeting consumer expectations.

Success Stories

Modern production techniques have made it possible to maintain flavor stability in non-alcoholic beers, offering a better experience for consumers.

IMPOSSIBREW® Production Methods

IMPOSSIBREW® has refined its brewing process by combining advanced methods and careful raw material selection. Using their proprietary Social Blend™ technology, they ensure consistent and appealing flavor profiles:

| Production Focus | Stability Approach | Outcome |

|---|---|---|

| Traditional Brewing | Controlled fermentation | Consistent base flavors |

| Social Blend™ Integration | Proprietary technology | Improved mouthfeel and stability |

| Quality Control | Strict ingredient selection | Reliable flavor reproduction |

Their Enhanced Lager and Enhanced Pale Ale showcase how fine-tuned production can result in stable, flavorful non-alcoholic beers. Other companies are also employing advanced methods to maintain flavor consistency.

Industry Examples

Beyond IMPOSSIBREW®, other companies are leading the way in flavor preservation with cutting-edge techniques.

Solos (by Prodalim) uses patented aroma capture technology to restore key flavors after dealcoholization. Christian Nett, CEO of WEINGUT BERGDOLT-REIF & NETT, praised their collaboration:

"Our collaboration with Solos allowed us not only to expand our product portfolio but also to present to the market the best products in terms of taste and feel. We are happy and satisfied with the work with Solos that allows us to be market leaders in this segment."

B&D Nutritional Ingredients' Flava-malt™ technology is another standout, adopted by breweries like Mother Earth Brewing and Naked Brewing to ensure consistent flavor profiles .

Additionally, Centec GMBH and Solos have partnered to innovate dealcoholization processes using FlavoLogic, maintaining flavor integrity throughout production .

These advancements fall into three main strategies:

- Advanced Aroma Recovery: Capturing and reintroducing volatile compounds to retain key aromas.

- Ingredient Innovations: Using specialized malts and natural modifiers to enhance texture and flavor.

- Collaborative Development: Partnerships between equipment makers and flavor experts to refine production techniques.

These approaches highlight how the industry is evolving to deliver better-tasting non-alcoholic beverages.

Conclusion

Key Points Summary

Non-alcoholic beer faces tough obstacles, primarily due to chemical changes like T2N formation - where just one gram can ruin over 26 million gallons of beer - and the lack of ethanol, which affects aroma and removes the characteristic 'burn' . Research from the University of Copenhagen by Sotirios Kampranis and Simon Dusséaux highlights a breakthrough: using baker's yeast cells to produce monoterpenoids. This method dramatically reduces water use by 10,000 times and cuts CO₂ emissions by 100 times compared to traditional hop farming . These hurdles require science-driven solutions.

Industry Next Steps

Addressing these chemical and sensory issues is crucial. The market's growth - from $15.09 billion in 2020 to $16.65 billion in 2021 - shows the rising demand for non-alcoholic beer. To meet this demand, brewers must focus on precise processes, high-quality raw materials, and rigorous quality checks:

| Focus Area | Implementation Strategy | Expected Impact |

|---|---|---|

| Process Control | Cold sterile filtration, pH management (<4.2) | Better freshness and stability |

| Raw Materials | LOX‐less barley, specialized malt | 50× reduction in T2N compounds |

| Quality Assurance | Regular testing, strict contamination controls | Consistent flavor profiles |

Professor Sotirios Kampranis explains: "After years of research, we have found a way to produce a group of small molecules called monoterpenoids, which provide the hoppy‐flavor, and then add them to the beer at the end of the brewing process to give it back its lost flavor. No one has been able to do this before, so it's a game changer for non‐alcoholic beer" .

For brewers, success in this growing market will depend on adopting advanced technologies, maintaining strict production standards, and ensuring top-notch quality. Those who tackle these challenges effectively will be well-positioned to lead in the expanding non-alcoholic beer segment.

Related Blog Posts

Next Generation Alcohol-Free Beer

IMPOSSIBREW®: The Enhanced Non-Alcoholic Beer designed as an alternative to full ABV beers using patent-pending technology*.

Enjoy a healthier daily wind down with the beer that matches the taste and feeling of traditional alcohol.

Keep the pleasure and ritual of drinking without worrying about your health.

Get Started

Next Generation Alcohol-Free Beer

IMPOSSIBREW®: The Enhanced Non-Alcoholic Beer designed as an alternative to full ABV beers using patent-pending technology*.

Enjoy a healthier daily wind down with the beer that matches the taste and feeling of traditional alcohol.

Keep the pleasure and ritual of drinking without worrying about your health.

Get StartedAward-winning Taste

Rated "UK's Best Non-Alcoholic Beer" by the prestigious World Beer Awards.

From 16 Calories / 100ml

Low Calorie. Low Carb. Vegan-friendly. <0.5% ABV. Gluten-Free (Lager)

Social Blend™

Our proprietary alcohol alternative made from a blend of science-backed ingredients designed to replicate the sensory, social and relaxing experience of drinking. Read more here.

Got Questions?

Find our most commonly asked questions below or ask our AI Brewer for instant answers.

What is IMPOSSIBREW®?

IMPOSSIBREW® is a pioneering non-alcoholic beer brand based in the UK that aims to create the world's most complete alcohol alternative using patent-pending technology.

Founded by Mark Wong in 2021 and working with some of the world's best professors, scientists and expert brewers, IMPOSSIBREW® specialises in expertly crafted non-alcoholic beers designed to match full ABV beers in both taste and feeling.

Product Range

IMPOSSIBREW® offers a range of enhanced non-alcoholic beers, including:

- Enhanced Lager (0.5% ABV)

- Enhanced Pale Ale (0.5% ABV)

- Limited Editions (Seasonal)

Key Benefits

The key feature that sets IMPOSSIBREW® apart is its proprietary "Social Blend™" - a combination of active botanical ingredients and nootropics using patent-pending technology* designed to recreate the relaxing effects of alcohol without the negative side effects.

Along with record-breaking quality flavour that comes from a unique process without removing alcohol.

Social Blend™ Ingredients

Developed with leading scientists in top UK universities, Social Blend™ includes:

- L-Theanine

- Ashwaghanda

- Soluble Plant Fibres

- Vitamin B1

- Various Plant Extracts.

These ingredients are chosen for their potential to boost serotonin, promote relaxation, and create a calming effect similar to the "one or two pint feeling" without hangovers.

See more details on our very own research paper, with over 1,000 participants:

- More than 70% said they felt relaxed after consuming IMPOSSIBREW®.

- 88% have reduced alcohol consumption since discovering IMPOSSIBREW®.

- 95% have told a friend about IMPOSSIBREW® after trying.

- 3/4 say that IMPOSSIBREW® is "the most complete alcohol alternative currently available on the market today".

Recognition

IMPOSSIBREW® has received several notable achievements:

- Featured on BBC's Dragons' Den

- Awarded the first and only Gold Medal in the No/Low beer category from the London Beer Competition

- Received multiple industry Gold awards in categories against Full-ABV beers

- Most followed No/Low Alcohol brand on TikTok globally.

Mission and Vision

IMPOSSIBREW® is on a mission to redefine non-alcoholic drinking by creating better-than-alcohol alternatives for those who love beer but want to avoid the health risks associated with alcohol consumption.

The company aims to become the global leading alcohol alternative brand, focusing on helping people transition to a healthier mode of relaxation without the traditional issues and side effects of alcohol.

Production and Ingredients

IMPOSSIBREW® combines traditional brewing methods with their proprietary Social Blend™ along with patent-pending technology*

The beers are made with traditional brewing ingredients such as water, malted barley, wheat, hops, and yeast, in addition to the Social Blend™ components - leveraging their unique cryogenic fermentation process, which means no alcohol is ever removed from the product - ensuring the most authentic quality taste you've come to expect.

Who is it for?

IMPOSSIBREW® caters to consumers who:

- Are busy professionals and parents who would like to unwind with a drink but don't want the hangovers.

- Enjoy the taste and relaxing experience of beer

- Are looking for healthier alternatives to alcohol, with lower calories, carbs and sugar

- Want to avoid hangovers and other negative effects of alcohol consumption

- Are interested in functional beverages with potential mood-enhancing properties

By offering a unique product that aims to replicate both the taste and feeling of alcoholic beer, IMPOSSIBREW® is positioning itself at the forefront of the growing non-alcoholic beverage market.

Get Started Today

Give it a try today with our Welcome Bundle and get 2 Free Beers with your first purchase. Get it delivered straight to your door, risk-free with our 30-day money-back guarantee.

We hope you enjoy them as much as we do and we can't wait for you to try.

*Patent pending in the UK under application number GB2415685.3

How does 'Social Blend™' work?

Social Blend™ is our proprietary alcohol alternative made from a blend of science-backed ingredients using patent-pending technology*.

Designed to replicate the sensory and social relaxing experience of drinking, minus the headaches (and bad decisions).

Developed with Dr Paul Chazot, Bioscience Professor and Chair of Pharmacology at Durham University.

Key Components and Mechanisms

- L-Theanine:

- Ashwagandha Root:

- Vitamin B1 (Thiamine):

- Various nootropic herbs:

Benefits

- Relaxation: The blend promotes a state of relaxation without the sedative effects typically associated with alcohol.

- Mental Calm: By boosting alpha brain waves and serotonin levels, it helps maintain a calm and focused mental state.

- Stress Relief: The combination of L-Theanine, Ashwagandha, and Vitamin B1 helps mitigate stress and anxiety.

- Mood Enhancement: The inclusion these ingredients and other botanicals supports mood regulation and overall positive outlook.

IMPOSSIBREW®'s Social Blend™ is a carefully crafted combination of nootropic and adaptogenic ingredients designed to offer a relaxing and mood-enhancing experience without the drawbacks of alcohol. It leverages the natural properties of its components to promote relaxation, reduce stress, and enhance mood, making it a unique alternative to traditional alcoholic beverages.

(Read our latest research paper here)

*Patent pending in the UK under application number GB2415685.3

Do you ship overseas?

We ship to the UK Mainland for free when you spend over £35

We aim to expand internationally soon - stay tuned!

If you have any queries, feel free to email: hello(@)impossibrew.co.uk

How long will it take to get my orders?

For UK mainland deliveries, normal orders processed here will take 1-3 business days to arrive, with an optional upgrade to Next Day Delivery available (12pm cut-off).

Delivery details will be provided in your confirmation email.

How is 0.5% ABV alcohol-free?

Yes, we know it's confusing. Isn't 0.5% ABV still alcoholic? Officially, 0.5% ABV is classified as Dealcoholised.

- In fact, most things we consume daily have more than 0.5% ABV

- Burger Rolls - 1.2% ABV

- Orange Juice - 0.5% ABV

- Ripe Banana - 0.5% ABV

After more than 2 years of research, we've found that the 0.5% ABV from our natural brewing process significantly increases both flavour and mouthfeel - without spiking your blood alcohol level (BAC).

Is it really gluten-free?

Yes, IMPOSSIBREW® Enhanced Lager is gluten-free. Even though it contains wheat and barley, our beers have been third-party tested to contain less than 10 parts per million (PPM) of gluten, which meets the criteria to be listed as, and labeled gluten-free.

Does it have alcohol tax?

No. While it is true that our beers don't contain alcohol, and thus don't incur UK alcohol duty, we'd like to highlight some factors here that might be helpful in reflecting the value we provide.

- One-to-One Brewing Process: At IMPOSSIBREW, we take pride in our unique brewing techniques. Unlike other non-alcoholic beers, our products are never diluted, watered-down, or have their alcohol content removed - and some even dilute their alcoholic beers up to 5x. This means that our brewing process involves the same level of craftsmanship, time, and resources as a traditional craft beer, resulting in comparable production costs.

- Effective Nootropics: In our commitment to creating the most relaxing non-alcoholic beers, we utilise only the highest quality nootropics as our active ingredients, in safe and effectives dosages. At current alcohol tax rates for a 5% ABV beer, the cost of our nootropics more than double that. Instead of contributing the amounts as tax, why not have it contribute to the product quality itself?

- Small Scale Brewing: Currently, we operate on a smaller scale, which makes us less competitive than large, commercial brewers (often +10,000x our brewing size). As a growing business, we are passionate about our mission to create unique, high-quality non-alcoholic experiences, and we truly appreciate your support. As we continue to grow and expand our production capabilities, we look forward to passing on even more savings to our valued community!

At IMPOSSIBREW, we prioritise offering our customers an enhanced, premium, non-alcoholic beer experience by combining innovative brewing techniques, quality active nootropic ingredients, and award-winning taste. While our pricing may differ from other non-alcoholic competitors, we believe that the value proposition and unique experience our beers provide are well worth it.

At the end of the day, tasting is believing. So give it a try and let us know what you think - risk-free with our IMPOSSIBREW® Guarantee.

Who shouldn't drink IMPOSSIBREW®?

It is not recommended for pregnant or breastfeeding women, those with certain medical conditions like GI disorders or hypertension, or individuals taking specific medications such as antidepressants, immunosuppressants or blood thinners. If you fall into any of these categories, it's best to consult with your doctor first.

Ashwagandha can lead to overstimulation (i.e. restlessness) if taken alongside thyroid medication.

What is your philosophy?

For thousands of years, we had only one way to unwind together. One way to let our guards down. One way to bridge the gap between who we are and who we are with others.

Not because it was perfect. But because it was all we had.

We decided that wasn't good enough.

We exist because we believe in a world where social connection doesn't demand compromise.

Where being present with others doesn't mean being absent from yourself. Where letting go doesn't mean losing control.This isn't about removing alcohol. This is about something better.

Our Social Blend™ technology isn't an accident. It's the result of questioning everything we thought we knew about social drinking. About working with scientists to understand what we're really seeking in these moments of connection. About daring to imagine something that wasn't possible before.

We believe the greatest innovations don't just solve problems - they change how we live. They make us question why we ever settled for less.

That's what we're building. Not just a drink, but a new way forward. A future where social connection comes without compromise. Where tradition meets innovation. Where science meets ritual.

This is the future of social drinking.

Got more questions?

Speak to our AI Brewer here for instant answers.

Or email us at hello@impossibrew.co.uk

Our customer support is available Monday to Friday: 9am - 5:30pm.