Functional beers are designed to offer more than just flavour - they include active ingredients like L-Theanine and Ashwagandha to promote relaxation and stress relief. However, ensuring these compounds remain effective requires precise brewing, storage, and packaging techniques. Here's what you need to know:

- Key Ingredients: Functional beers often include botanical extracts, nootropics, and vitamins for specific benefits.

- Stability Challenges: Active compounds can degrade during brewing or storage, requiring careful temperature control and UV-protective packaging.

- Consumer Impact: 71% of users reported enhanced relaxation, and 88% reduced alcohol consumption after trying functional beers.

- UK Regulations: Strict standards ensure safety, quality, and ingredient stability in these products.

Functional beers like those from IMPOSSIBREW® use advanced techniques, such as cryogenic fermentation and amber glass bottles, to maintain the stability of active compounds throughout their shelf life. This ensures consistent benefits and taste for consumers.

Active Compounds in Functional Beer

Main Ingredients

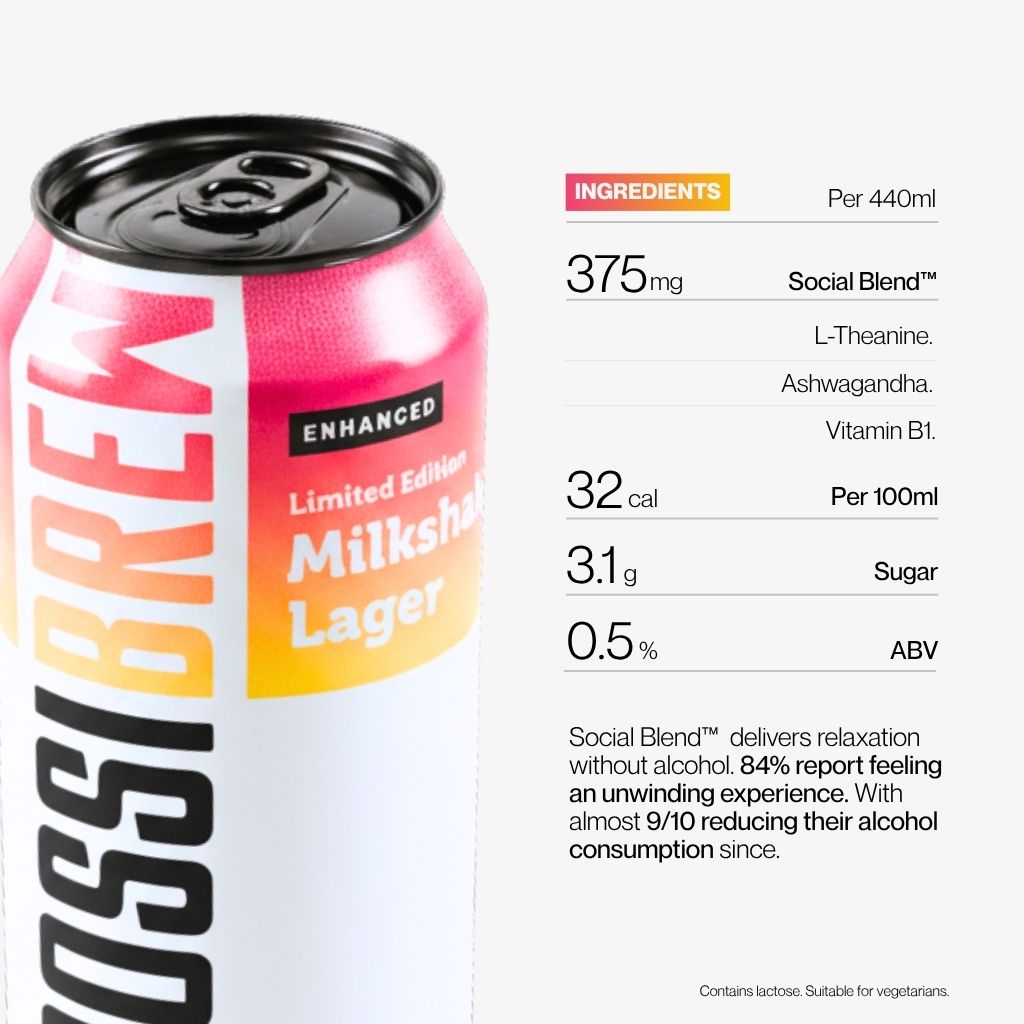

Functional beers are crafted with specific bioactive ingredients designed for targeted effects. For example, IMPOSSIBREW®'s Social Blend™ combines L-Theanine, Ashwagandha root, Vitamin B1, and various plant extracts. These ingredients are carefully selected for their stability and effectiveness throughout the brewing and storage process. Maintaining the right balance is key to preserving their properties over time.

Effects and Benefits

The active compounds in functional beer are designed to work together, creating combined effects that deliver noticeable results. For instance, research on IMPOSSIBREW®'s Social Blend™ found that 71% of customers experienced enhanced relaxation [1].

"Our Social Blend™ technology isn't an accident. It's the result of questioning everything we thought we knew about social drinking. About working with scientists to understand what we're really seeking in these moments of connection. About daring to imagine something that wasn't possible before." - IMPOSSIBREW® [1]

The development of these blends is backed by scientific research and overseen by experts, such as Dr Paul Chazot, a Bioscience Professor and Chair of Pharmacology at Durham University.

| Active Compound | Function | Observed Effect |

|---|---|---|

| L-Theanine | Relaxation Support | Promotes calmness |

| Ashwagandha Root | Stress Relief | Reduces tension |

| Vitamin B1 | Nutritional Support | Supports metabolism |

| Plant Extracts | Mood Enhancement | Boosts serotonin levels |

UK Safety Standards

In the UK, strict regulations govern the use of functional ingredients in beverages to ensure both safety and innovation. Active compounds must meet rigorous stability requirements and undergo extensive testing during production.

For functional beers, manufacturers must follow precise rules regarding ingredient concentrations and stability. For example, gluten-free varieties like IMPOSSIBREW®'s Enhanced Lager keep gluten levels below 10 parts per million (PPM) [1].

Key regulatory measures include:

- Regular stability testing of active ingredients

- Strict quality control protocols

- Full traceability of all ingredients

- Comprehensive documentation of production processes

- Frequent safety assessments

These regulations ensure that functional beers maintain their benefits and remain safe for consumers throughout their shelf life.

Production Stability Factors

Brewing Process Effects

Maintaining the stability of active compounds during brewing is crucial. IMPOSSIBREW® uses a cryogenic fermentation process that keeps fermentation temperatures low to protect both the flavour and the properties of key ingredients like L-Theanine and Ashwagandha [1]. By managing temperatures carefully in the early stages, this method helps preserve the molecular structure of these delicate compounds, ensuring the desired relaxation effects remain intact.

Production Conditions

Precise production conditions play a key role in maintaining the stability of the functional ingredients used in Social Blend™. IMPOSSIBREW® employs strict environmental controls throughout the manufacturing process to safeguard the integrity of these compounds. This careful management addresses potential challenges tied to ingredient stability.

Compound-Specific Issues

Active compounds can react differently during production, requiring tailored solutions. IMPOSSIBREW®'s proprietary Social Blend™ technology includes specific protocols designed to protect the unique properties of each ingredient [1]. This ensures consistent quality across their products, such as the Enhanced Lager, which is gluten-free and contains less than 10 parts per million of gluten [1].

Storage and Shelf Life

Storage Requirements

Storing functional beers correctly is key to keeping their active compounds stable. Factors like temperature, light, and heat exposure play a big role in preventing the breakdown of these compounds. To tackle this, IMPOSSIBREW® uses amber glass bottles designed to block harmful UV rays. Consistent temperature and humidity levels are also maintained to ensure the ingredients stay effective.

Packaging Methods

The way functional beers are packaged can make a big difference in protecting their quality. By minimising exposure to oxygen, light, and temperature changes, packaging helps keep the active compounds intact. IMPOSSIBREW® employs advanced techniques to create a controlled environment within the bottle, ensuring the ingredients stay in top condition.

Shelf Life Data

When stored under the right conditions, the active compounds in the beer remain stable throughout its shelf life. Ongoing stability tests confirm that the ingredients retain their benefits over time, ensuring a consistent taste and experience. These strict storage and packaging practices align perfectly with the production processes to deliver a reliable product every time.

sbb-itb-a752bf8

What's really in our beer?

Product Development Steps

After ensuring rigorous production and storage protocols, the next step in product development focuses on refining ingredient stability.

Maintaining Effectiveness

Ingredients like L-Theanine and Ashwagandha are chosen for their ability to deliver consistent benefits over time. Using its patent-pending Social Blend™ technology, IMPOSSIBREW® ensures these active compounds stay stable and effective throughout the product's lifecycle.

According to data, 71% of consumers report improved relaxation after using the product [1]. This highlights how carefully developed strategies can preserve the product’s benefits from start to finish.

Testing and Fine-Tuning

Ongoing testing is critical to ensure compound stability. Regular monitoring and adjustments address any challenges that arise, keeping formulations on track. IMPOSSIBREW® collaborates with scientists and expert brewers to refine its blends, ensuring every batch meets high standards of quality [1].

This dedication to testing and improvement has paid off - IMPOSSIBREW®'s Lager & Pale were named the UK's best non-alcoholic beers at the 2023 World Beer Awards [1].

Stability Techniques

Exploring various stability techniques is key to success. For example, IMPOSSIBREW® uses specialised brewing methods like cryogenic fermentation. This process helps protect delicate compounds while maintaining both functionality and flavour [1].

The results speak for themselves: 88% of IMPOSSIBREW® customers have reduced their alcohol intake after discovering the brand [1]. These methods ensure the product remains reliable and consistent as it heads into final quality checks.

Conclusion

Carefully managed production and storage processes ensure that functional beers retain their active compounds, consistently offering the intended effects to consumers. This precision has translated into measurable success for IMPOSSIBREW®, with 71% of customers reporting improved relaxation effects [1].

The 2023 World Beer Awards highlighted IMPOSSIBREW® for its consistent quality and flavour. This recognition underscores their ability to balance compound stability with delivering a high-quality taste experience [1].

With proven methods and continuous research, the brand is set to refine its offerings further. By combining strict quality controls with advanced brewing techniques, functional beers are able to maintain their active properties throughout production and storage. This scientific approach ensures a premium non-alcoholic option that delivers on both benefits and flavour.

FAQs

How are active compounds like L-Theanine and Ashwagandha kept stable in functional beers during production and storage?

The stability of active compounds such as L-Theanine and Ashwagandha in functional beers depends on careful formulation and production techniques. These compounds are typically added at specific stages of brewing to preserve their beneficial properties. Additionally, controlled storage conditions, such as maintaining appropriate temperatures and protecting the beer from excessive light exposure, help ensure their stability over time.

Producers like IMPOSSIBREW® use science-backed methods to craft their enhanced non-alcoholic beers, ensuring that active ingredients remain effective while delivering a satisfying sensory experience. By combining innovation with meticulous quality control, functional beers can retain their active compounds throughout their shelf life.

How are active ingredients in functional beers preserved during brewing and storage?

The stability of active ingredients in functional beers is carefully managed through precise brewing techniques and controlled storage conditions. Key factors include maintaining optimal temperatures, monitoring pH levels, and using specialised brewing processes to protect the integrity of these compounds. Proper packaging also plays a crucial role in shielding the beer from light and oxygen, which can degrade active ingredients over time.

For example, IMPOSSIBREW® incorporates scientifically backed methods to ensure the effectiveness of their proprietary Social Blend™, delivering a consistent and enjoyable experience with every sip. Their commitment to quality ensures that the active components remain stable throughout production and storage, providing the desired sensory and social benefits without compromise.

What are the UK regulations on the safety and stability of active compounds in functional beers, and how do they influence product quality?

In the UK, functional beers must comply with food safety regulations, including those set out by the Food Standards Agency (FSA) and relevant EU-derived legislation. These regulations ensure that all ingredients, including active compounds, are safe for consumption and accurately labelled. Stability testing during production and storage is crucial to maintain the quality and effectiveness of these active compounds over time.

For example, producers like IMPOSSIBREW® use science-backed methods to ensure their non-alcoholic beers, such as the Enhanced Lager and Enhanced Pale Ale, retain their functional benefits while meeting regulatory standards. This commitment to safety and quality helps deliver a consistent and enjoyable experience for consumers.