Vacuum distillation is a low-temperature method used by breweries to remove alcohol from beer while preserving its flavour and aroma. By reducing air pressure, alcohol evaporates at around 40°C instead of the usual 78.3°C, avoiding heat damage to delicate compounds. This process is energy-efficient, allows precise control over alcohol content, and produces high-quality non-alcoholic beer that closely resembles its alcoholic counterpart. However, it requires advanced equipment, skilled operation, and reintroducing carbonation for proper texture.

Key Points:

- How it works: Lower pressure reduces alcohol’s boiling point, protecting flavour.

- Advantages: Preserves taste, uses less energy, and ensures consistent quality.

- Challenges: High costs, some flavour loss, and technical complexity.

- Comparison: Outperforms methods like reverse osmosis and arrested fermentation in flavour retention.

In the UK, brands like IMPOSSIBREW® use vacuum distillation to meet rising demand for premium non-alcoholic beer, offering options that satisfy both taste and social drinking experiences.

ABV Technology: Changing How Breweries Make Non Alcoholic Beverages

Step-by-Step Process of Vacuum Distillation

Vacuum distillation plays a key role in crafting non-alcoholic beer by removing alcohol while keeping the flavour intact. Here's a closer look at how the process unfolds.

Preparation and Initial Setup

The journey starts with traditional fermentation, where the beer develops its full flavour profile[4]. This step is crucial, as it lays the groundwork for the taste that will remain in the final product.

Once the beer is ready, the vacuum distillation equipment is prepared. This includes setting up a vacuum chamber, heating system, and condensation apparatus[7]. The beer is transferred into the distillation vessel, and critical parameters like temperature, pressure, and flow rates are carefully calibrated to ensure alcohol is removed without damaging the delicate flavour compounds[2]. The vacuum pump is then activated, lowering the chamber's atmospheric pressure to below 200 mbar - a level ideal for this process[5]. With everything in place, the focus shifts to the alcohol removal phase.

Vacuum Application and Alcohol Removal

Applying the vacuum reduces the atmospheric pressure inside the chamber, which in turn lowers ethanol's boiling point from the usual 78.3°C to a much gentler 40–60°C[1][4]. This allows the alcohol to evaporate at lower temperatures, preserving the beer's essential flavour compounds[2][7]. The evaporated alcohol vapour is captured and removed, leaving behind beer with significantly reduced alcohol content.

However, this step comes with challenges. Some volatile compounds, like esters and higher alcohols that contribute to the beer's aroma and taste, can be partially lost during the process[5]. Advanced systems address this by using fractionation columns, which help recover desirable volatiles while letting unwanted alcohol escape. Interestingly, compounds like diacetyl - responsible for certain buttery notes - are not removed during vacuum distillation, which helps retain specific flavour nuances[5]. Once the alcohol is removed, the focus shifts to recovering and restoring any lost aroma compounds.

Aroma Recovery and Reintroduction

Alcohol removal can lead to the loss of some volatile aroma compounds that define the beer's unique smell and taste. To counter this, advanced vacuum distillation systems include aroma recovery techniques. These systems capture the volatile compounds during a separate condensation stage and carefully reintroduce them into the dealcoholised beer, restoring its original sensory profile[2][5].

Finally, carbonation is reintroduced. Since the natural CO₂ produced during fermentation is removed during vacuum distillation, breweries inject CO₂ during canning or bottling. This step ensures the beer retains its characteristic mouthfeel and texture, delivering the experience consumers expect from a quality brew[1][7].

Benefits and Drawbacks of Vacuum Distillation

Now that we've explored the vacuum distillation process, it's time to weigh its upsides and challenges. Like any production technique, vacuum distillation has strengths and limitations that influence its suitability for breweries of varying sizes and production goals.

Key Benefits of Vacuum Distillation

One of the standout advantages of vacuum distillation is its ability to preserve flavour. By operating at a much lower temperature - around 38°C instead of the usual 78.3°C - it protects delicate aroma compounds from heat damage. This results in non-alcoholic beers that retain authentic taste profiles, closely mirroring their alcoholic counterparts.

Another perk is its energy efficiency. Since the process requires less heat and shorter operating times compared to traditional methods, it can be more economical. This is especially important as the brewing industry increasingly focuses on reducing energy use and cutting carbon emissions.

Vacuum distillation also offers brewers precise control over the final product. It allows for fine-tuning of alcohol content while safeguarding the beer's sensory characteristics. This level of precision is particularly valuable for premium brands that prioritise consistent quality across batches.

Challenges and Limitations

Despite its benefits, vacuum distillation isn't without its hurdles. For starters, the cost of equipment and operation is steep. The significant upfront investment can make it a less viable option for smaller craft breweries.

Another drawback is the potential loss of volatile compounds. Even at reduced temperatures, some aroma and flavour elements - like esters - may escape during the process. While advanced systems often include aroma recovery features, perfectly replicating the original flavour remains a challenge.

The process also comes with technical complexity. Operating and maintaining vacuum distillation systems requires skilled personnel and regular upkeep. This adds to the operational costs and complexity. Additionally, breweries need to use forced carbonation to recreate the traditional beer texture, which demands precision and expertise.

Pros and Cons Comparison Table

| Advantages | Disadvantages |

|---|---|

| Preserves flavour and aroma | High equipment and operational costs |

| Energy-efficient and cost-effective | Partial loss of volatile compounds |

| Allows precise control of alcohol content | Requires forced carbonation for texture |

| Ideal for premium, large-scale production | Less accessible for smaller breweries |

| Enhances brand image as authentic beer | Demands skilled operation and maintenance |

| Operates at lower temperatures to protect compounds | Complex setup and calibration needed |

Ultimately, whether vacuum distillation is the right choice depends on a brewery's scale, budget, and quality goals. While it excels in flavour preservation and energy efficiency, the high initial investment and operational demands often make it more suitable for larger breweries or those collaborating with specialised facilities. This explains why some brands, like IMPOSSIBREW®, opt for this method to craft premium non-alcoholic beers.

sbb-itb-a752bf8

Comparison with Other Alcohol Removal Methods

When it comes to removing alcohol from beer, the method you choose can significantly impact the final product. Each technique has its own advantages and limitations, affecting everything from flavour to cost efficiency. Let's see how vacuum distillation compares to other popular methods.

Reverse Osmosis vs Vacuum Distillation

Reverse osmosis works by using a semipermeable membrane to separate alcohol from the beer while keeping the flavour compounds intact. The concentrated flavour-rich liquid is then diluted with water to create non-alcoholic beer[3][7]. While effective, this process comes with some downsides: it requires costly equipment, takes longer to complete, and uses a lot of water.

Vacuum distillation, by contrast, removes alcohol at a much lower temperature - around 37–40°C - thanks to reduced pressure. This gentle process helps preserve the beer's aroma and flavour, giving it a more authentic taste profile[2][1][4]. Although it also requires specialised equipment and precise control, vacuum distillation generally offers better efficiency and scalability.

Arrested Fermentation vs Vacuum Distillation

Another approach, arrested fermentation, stops the brewing process early to prevent yeast from producing significant amounts of alcohol. This method is appealing because it requires minimal investment in specialised equipment and is relatively simple to implement[3][4]. However, there’s a catch: beers made this way often lack complexity. Since the yeast doesn’t complete its work, the beer can taste overly sweet, and brewers may need to add artificial flavourings to replicate traditional beer characteristics[3][4].

Vacuum distillation, on the other hand, allows for full fermentation, ensuring the beer develops its complete range of flavours. The alcohol is then gently removed, resulting in a non-alcoholic beer that closely resembles its original taste[2][1][4].

Alcohol Removal Methods Comparison Table

| Method | Flavour Retention | Equipment Cost | Scalability | Process Complexity | Accessibility | Environmental Impact |

|---|---|---|---|---|---|---|

| Vacuum Distillation | High | Moderate-High | High | High | Medium | Energy-efficient |

| Reverse Osmosis | Medium-High | Very High | High | High | Low | Water-intensive |

| Arrested Fermentation | Low-Medium | Low | Medium | Low | High | Low |

The choice of method depends on what matters most to the brewery. Larger operations that prioritise authentic flavours might lean towards vacuum distillation for its ability to preserve the beer's character, or even reverse osmosis despite its higher costs. Smaller breweries, on the other hand, may start with arrested fermentation due to its simplicity and lower investment requirements. Interestingly, mobile or contract dealcoholisation services are becoming more common, giving smaller producers access to advanced techniques like vacuum distillation without the need for heavy upfront costs[3].

UK Applications: IMPOSSIBREW® Case Study

The non-alcoholic beer market in the UK is booming as more people embrace healthier lifestyles. Leading this shift is IMPOSSIBREW®, a brand that combines vacuum distillation with advanced brewing techniques to craft premium alcohol-free beers that meet the expectations of British drinkers.

How IMPOSSIBREW® Uses Vacuum Distillation

IMPOSSIBREW® has perfected the art of using vacuum distillation to preserve the rich flavours of its beers. The process involves placing fully fermented beer into a vacuum chamber, which lowers the boiling point of alcohol. This method ensures that delicate flavour compounds, often lost in high-temperature alcohol removal, remain intact[1]. To further enhance the taste, the company uses aroma recovery techniques and carefully manages distillation parameters to retain the beer’s sensory profile[1][5].

Once the alcohol is removed, carbonation is reintroduced during packaging to give the beer the right texture and mouthfeel. This meticulous process ensures that their Enhanced Lager and Enhanced Pale Ale deliver a drinking experience that closely mirrors traditional beers, earning praise from UK consumers for their consistent quality.

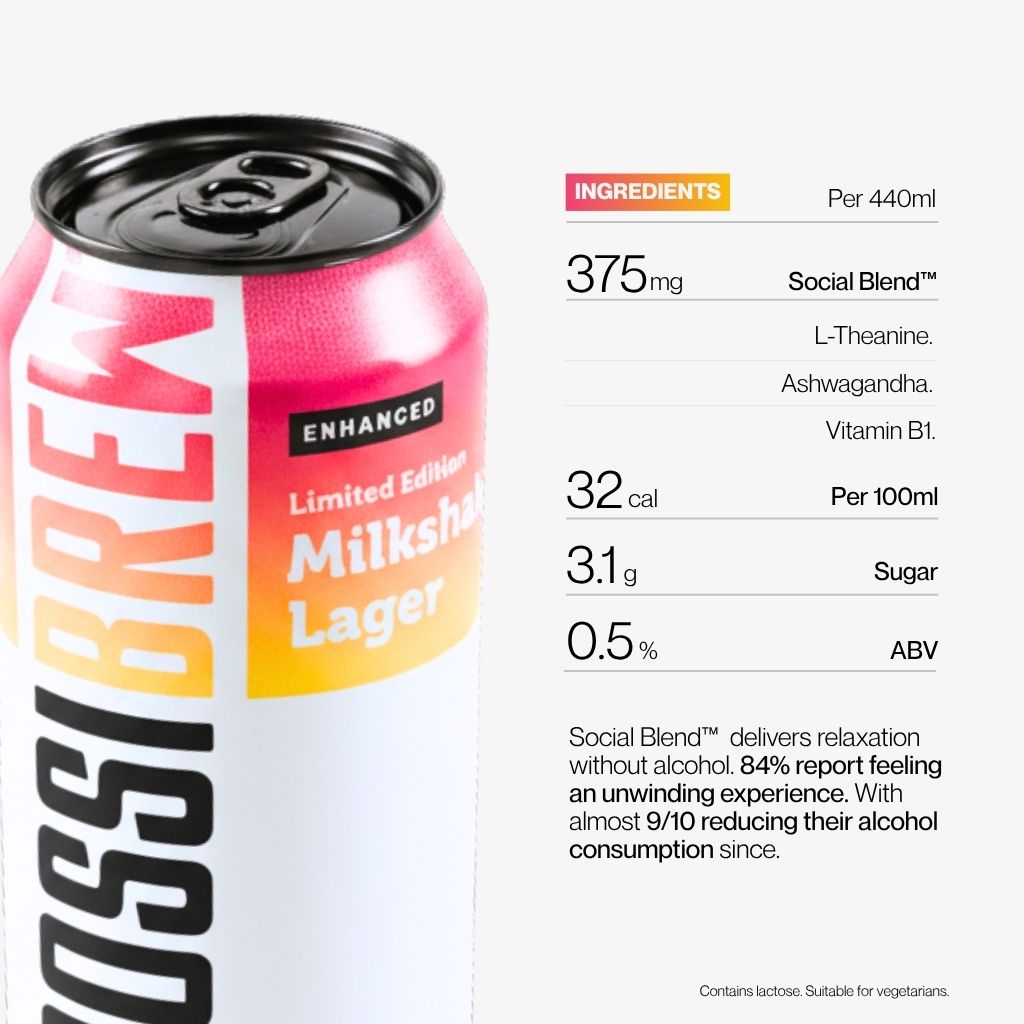

The Role of Social Blend™ in the Drinking Experience

IMPOSSIBREW® goes beyond just removing alcohol by incorporating its trademark Social Blend™ to enhance the overall experience. This unique formula is made with nootropic and adaptogenic ingredients, designed to replicate the calming, social effects of traditional beer.

One of the common drawbacks of non-alcoholic beers is the absence of that subtle relaxation people associate with drinking. IMPOSSIBREW® addresses this gap, and many UK reviews highlight how the Social Blend™ makes their beers feel closer to conventional options. It ensures that social occasions are just as enjoyable, without the worry of hangovers or impaired judgement.

By pairing advanced brewing techniques with functional ingredients, IMPOSSIBREW® is raising the bar for non-alcoholic beers in the UK, offering more than just an alcohol-free alternative - it’s creating a genuinely satisfying social drink.

Key Features of IMPOSSIBREW® Beers for UK Consumers

IMPOSSIBREW®'s beers are crafted with the health-conscious UK audience in mind. Their Enhanced Lager, with less than 0.5% ABV, delivers a crisp, dry taste with a refreshing citrus finish, appealing to traditional lager lovers. Meanwhile, the Enhanced Pale Ale taps into the UK’s growing craft beer scene, offering tropical fruit notes and a smooth texture. Both options are low in calories, making them ideal for those mindful of their diet but unwilling to compromise on the social joy of beer.

The brand also caters to diverse dietary needs. All their beers are vegan-friendly, and the Enhanced Lager is gluten-free, making them accessible for a wide range of consumers. Whether at pubs, restaurants, or gatherings, these beers can be enjoyed by almost everyone.

Sustainability is another priority for IMPOSSIBREW®, as they use natural ingredients and align with the increasing environmental awareness among British consumers. At £1.97 per can, their beers are competitively priced within the premium segment, reflecting both their advanced brewing methods and the added value of the Social Blend™.

For those looking for variety, limited seasonal editions keep things exciting, while the Bestseller Bundle - priced at £49.99 and including 18 beers, a free glass, and free delivery - offers great value for regular buyers. This pricing strategy strikes a balance between affordability and the premium quality of their products.

Industry experts have noted that IMPOSSIBREW® is setting a new standard in the UK’s alcohol-free beer market. By combining vacuum distillation with the innovative Social Blend™, the brand has created beers that don’t just replace traditional options - they rival them.

Conclusion and Key Takeaways

Why Vacuum Distillation Stands Out

Vacuum distillation offers a way to craft non-alcoholic beer that doesn’t sacrifice flavour. By lowering the boiling point of alcohol, this method preserves the essential taste components that make beer enjoyable [1][6]. It’s a gentle process, allowing brewers to create alcohol-free versions that closely resemble their traditional counterparts.

This technique isn’t just about taste - it’s also more efficient. It cuts down on energy consumption and processing time, making it a more environmentally friendly option [2]. For breweries looking to reduce their carbon footprint while maintaining high standards, vacuum distillation is a smart choice.

Another key advantage is the precise control it gives over flavour profiles. Brewers can ensure consistency across batches, which is essential for meeting consumer expectations [2]. Together, these factors highlight why vacuum distillation is becoming a cornerstone of non-alcoholic beer production.

What’s Next for Non-Alcoholic Beer in the UK?

With these technical benefits driving change, the UK’s non-alcoholic beer market is on a steady rise. Sales have jumped by over 30% recently [2], reflecting a shift in how Brits approach drinking. Alcohol-free options are no longer seen as compromises - they’re becoming premium choices that fit seamlessly into modern lifestyles.

Vacuum distillation is at the heart of this transformation [2]. As more breweries adopt this advanced process, the gap between alcoholic and non-alcoholic beer continues to narrow. The focus on quality is reshaping perceptions, with premium alcohol-free beers now standing shoulder to shoulder with their traditional counterparts.

Looking ahead, innovations like mobile dealcoholisation units and contract brewing are set to make vacuum distillation accessible to smaller craft breweries [3]. This will open the door to even more creativity and variety in the market, offering UK consumers a wider selection of high-quality alcohol-free beers.

The future looks promising. With vacuum distillation leading the charge, non-alcoholic beer in the UK is poised to deliver authentic, satisfying experiences that meet the demands of today’s discerning drinkers.

FAQs

How does vacuum distillation compare to reverse osmosis for preserving flavour and energy efficiency?

When it comes to producing non-alcoholic beer, vacuum distillation and reverse osmosis are two of the most commonly used methods, each with its own effects on flavour and energy efficiency.

Vacuum distillation works by lowering the boiling point of alcohol through reduced pressure, allowing it to be removed at much lower temperatures. This gentle process helps to preserve the beer's delicate flavours by minimising heat exposure, making it a great option for maintaining the original taste of the beverage.

Reverse osmosis, on the other hand, uses a filtration system to separate alcohol and water molecules from the beer. While this method is known for being energy-efficient, it can sometimes remove some of the flavour compounds, which may impact the overall taste.

For those who prioritise a premium drinking experience, brands like IMPOSSIBREW® stand out. They utilise advanced techniques and carefully selected ingredients to create non-alcoholic beers that closely mimic the taste and feel of traditional brews, ensuring no compromise on quality.

What challenges do smaller breweries face when using vacuum distillation to produce non-alcoholic beer?

Smaller breweries often run into a few hurdles when trying to use vacuum distillation to produce non-alcoholic beer. One of the biggest obstacles is the high cost of equipment. The systems needed for vacuum distillation come with a hefty price tag, making it tough for smaller operations to handle the initial investment.

Another issue is the technical know-how required to manage this process. Vacuum distillation is a delicate procedure that needs close attention to maintain the beer's flavour and overall quality. On top of that, many smaller breweries face space constraints, as the equipment can take up a significant amount of room, which isn’t always available in their facilities.

Still, vacuum distillation remains a go-to method for creating non-alcoholic beer that tastes just like the real thing. It’s a reliable way to deliver the authentic flavours that fans of non-alcoholic beer love.

How does vacuum distillation preserve the flavour of non-alcoholic beer through aroma recovery?

Vacuum distillation is a method used to remove alcohol from beer while keeping its flavour profile intact. By lowering the pressure during the process, the boiling point of alcohol drops significantly. This means the alcohol can be separated at much lower temperatures, which helps preserve the beer's delicate aromas and flavours that might otherwise be lost with higher heat.

To keep the flavour as close to the original as possible, aroma recovery techniques are also used. These methods capture the volatile compounds that give the beer its distinctive taste and aroma and reintroduce them into the final product. This careful process ensures that non-alcoholic beer retains the rich sensory experience of the original brew.